Categories

Tags

Archives

Residential and Commercial Needs Seen from a WPC Door Factory P

-

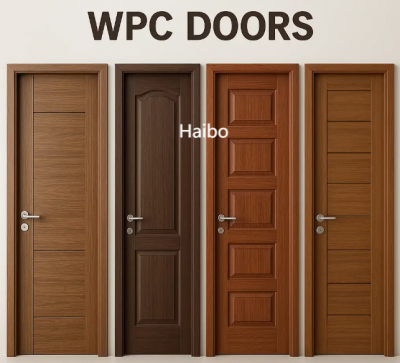

The global demand for door products has been steadily shifting between residential buildings and commercial projects. A WPC Door Factory —specializing in wood plastic composite materials—offers a valuable window into how these demands evolve. With the growth of eco-conscious design and long-term durability concerns, WPC doors have become an appealing option across various settings.

Residential Demand: Durability and Design Matter More Than Ever

In the residential sector, demand for WPC doors is experiencing a steady climb. Homeowners today prioritize materials that resist moisture, termites, and warping—especially in regions with humid or unstable climates. WPC doors fit this niche well, combining the look of wood with the resilience of engineered materials. A modern WPC Door Factory often caters to custom designs for bedrooms, kitchens, and bathrooms, where both form and function are key.

Another driving factor in residential growth is renovation activity. With more people opting to upgrade existing homes rather than purchase new ones, demand for affordable, easy-to-install door options is rising. Here again, WPC doors serve a growing need, as they are lightweight, easy to handle, and offer a clean, modern aesthetic.

Commercial Sector: Demand Fluctuates with Business Trends

On the commercial side, the picture is more varied. While WPC doors are still favored in specific environments like offices, healthcare buildings, and educational institutions, the pace of demand depends on the broader real estate cycle. In recent years, some commercial developments have slowed in certain regions, affecting bulk orders from this segment.

That said, WPC doors are being used creatively in hospitality and retail spaces where low maintenance and design flexibility are key. A WPC Door Factory may now offer options with acoustic features or enhanced fire resistance—valuable traits for large commercial settings. Even so, commercial buyers often look for standardized designs in large volumes, leading to more rigid product requirements than in residential orders.

Material Trends and Sustainability Considerations

One unifying trend across both sectors is the preference for environmentally conscious building materials. WPC doors, made from recycled wood fiber and plastic resin, meet this growing need. They require less finishing, generate less waste, and offer long service life without regular painting or polishing. A WPC Door Factory that can highlight these benefits is well-positioned to serve both growing home projects and selective commercial contracts.

While residential construction is expected to remain steady in the short term, the commercial sector may fluctuate more sharply with macroeconomic shifts. For a WPC Door Factory, flexibility in design and manufacturing processes is essential. Offering customizable yet scalable door solutions helps meet the distinct needs of homeowners and property developers alike. For more about door products that meet evolving project demands, visit https://www.haibodoor.com/news/industry-news/inside-a-wpc-door-factory-what-is-a-wpc-door.html .